Single Row Ball Bearing - 686

| Products

62 Series

Bearing Series > Single Row Ball Bearings > 600 Series > 686

686

Single Row Deep Groove Ball Bearings are widely recognized as the predominant type of rolling bearing, featuring inner and outer ring raceway grooves that form a circular arc with a radius slightly larger than that of the balls.

Brand

ZHY

Cage Material

Steel

Bearing Industry Number

686

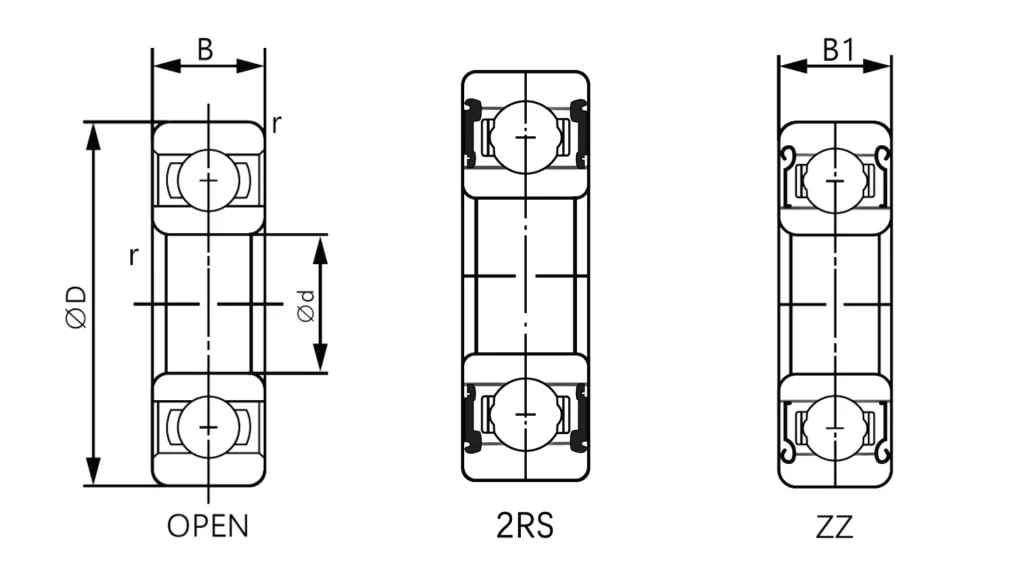

Closure

Customizable

Bore Diameter

6 mm

Number of Rows

1

Bore Diameter Tolerance

+0 / -0.007 mm

Maximum Temperature

100°C / 212°F (Customizable)

Outside Diameter

13 mm

Minimum Temperature

-30°C / -22 °F (Customizable)

Outside Diameter Tolerance

+0 / -0.007 mm

Dynamic Radial Load Capacity

1080 N

Outer Ring Width

3.5 mm (Open) / 5 mm (Capped)

Static Radial Load Capacity

438 N

Fillet Radius

0.15 mm

Maximum Speed

37000/44000 rpm (Grease/Oil)

Ring Material

AISI 52100

Lubricant Material

Grease or Oil

Ball Material

AISI 52100 (Steel) / Si3N4 (Ceramic)

ABEC Rating

3 (Customizable)

Brand

ZHY

Bearing Industry Number

686

Bore Diameter

6 mm

Bore Diameter Tolerance

+0 / -0.007 mm

Outside Diameter

13 mm

Outside Diameter Tolerance

+0 / -0.007 mm

Outer Ring Width

3.5 mm (Open) / 5 mm (Capped)

Fillet Radius

0.15 mm

Ring Material

AISI 52100

Ball Material

AISI 52100 (Steel) / Si3N4 (Ceramic)

Cage Material

Steel

Closure

Customizable

Number of Rows

1

Maximum Temperature

100°C / 212°F (Customizable)

Minimum Temperature

-30°C / -22 °F (Customizable)

Dynamic Radial Load Capacity

1080 N

Static Radial Load Capacity

438 N

Maximum Speed

37000/44000 rpm (Grease/Oil)

Lubricant Material

Grease or Oil

ABEC Rating

3 (Customizable)

Key Features:

- Support for both radial and axial loads.

- Efficient management of radial and axial loads in both directions.

- Demonstrated reliability and versatility, making them prevalent across various applications.

Key Benefits:

- Ideal for noise-sensitive environments.

- Suitable for equipment requiring noise and vibration reduction due to low frictional torque and high rotational speed.

Applications:

- Industrial motors and servomotors

- Stepper motors, electric machinery, and robotics

- Agricultural equipment including tractors and string trimmers

- Textile machines and film rolling mills

- Conveyors and material handling systems

- Powder and particle clutches

- Automotive components and wheel assemblies

- etc.