A Complete Guide to Skateboard Bearings: Types, Price & Suppliers

Skateboard bearings are essential components that significantly impact the performance of a skateboard. Whether you’re a skateboard manufacturer, supplier, or distributor, understanding the intricacies of skateboard bearings is crucial. This guide provides a comprehensive overview of the different types of bearings, factors to consider when choosing them, and how to select the best suppliers.

This blog talks about skateboard bearings and what’s best for wholesale B2B suppliers and distributors looking for best skateboard bearing manufacturers.

What Are Skateboard Bearings?

Skateboard bearings are small circular devices fitted inside the skateboard wheels to allow smooth and fast rotation. They consist of several parts: an outer race, an inner race, steel or ceramic balls, and a retainer. These components work together to minimize friction and enhance the skateboard’s speed and performance.

Types of Skateboard Bearings for B2B Suppliers

Understanding the types of skateboard bearings is key to making the right choice for your needs:

Standard Skateboard Bearings

These are the most common types used by skaters. They usually come in the standard size 608 bearings, which fit most skateboard wheels.

High-Performance Skateboard Bearings

Often made of ceramic, these bearings offer reduced friction, increased durability, and higher speeds. They are ideal for competitive skating.

Custom Skateboard Bearings for B2B Skateboard Suppliers

Custom bearings can be tailored to specific needs, such as enhanced durability or unique designs. These are a great option for brands looking to differentiate their products.

If you want to create custom bearings of your own size and type, visit our custom bearings page.

Choosing the right skateboard bearings is critical for ensuring the performance, safety, and durability of the skateboard. For B2B suppliers, wholesale buyers, manufacturers, and distributors, understanding these key considerations will help you select the best bearings for your needs.

Key Considerations for B2B Suppliers When Choosing Skateboard Bearings

Material Composition of Skateboard Bearings

The material of skateboard bearings plays a crucial role in their overall performance, lifespan, and cost-effectiveness. Different materials offer varying levels of durability, speed, and resistance to environmental factors.

Steel Bearings

Steel bearings are the most commonly used in the skateboard industry due to their durability and affordability. They provide a smooth ride and are resilient under typical skateboarding conditions. However, they are prone to rust if exposed to moisture, making maintenance crucial.

Ideal for general-purpose skateboarding and suitable for all skill levels. For bulk orders, steel bearings offer a cost-effective solution without compromising quality.

Ceramic Bearings

Ceramic bearings are known for being lighter than steel, offering less friction and thus faster speeds. They are resistant to rust, making them a preferred choice in wet or humid conditions.

Often considered the best skateboard bearings, ceramic bearings are ideal for professional skateboarders who require high performance. They come at a higher price point but offer superior speed and longevity.

To explore our range of steel and ceramic bearings, visit our industries served page to see how our bearings are used in sports and recreation.

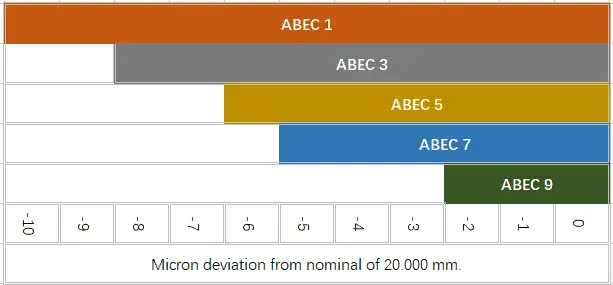

Understanding ABEC Ratings For Bearings

The precision of skateboard bearings is measured using the ABEC (Annular Bearing Engineers’ Committee) rating system. This system is crucial for determining the bearing’s efficiency, smoothness, and potential speed.

Image Credits: TFL Bearings

ABEC Rating | Skateboard Category | Performance & Use |

ABEC 1-3 | Entry-level Skateboards | Least precise; suitable for casual skateboarding, offers adequate performance. Ideal for beginners or budget-conscious users. |

ABEC 5-7 | Mid to High-end Skateboards | Common in most skateboards; balances speed, durability, and cost. Suitable for a wide range of activities, from casual to semi-professional use. |

ABEC 9 and Above | Professional Skateboards | Highly precise; used in competitive skateboarding for maximum speed and minimal friction. Best for high-speed applications and professional use. |

Understanding ABEC Ratings

Equivalent standards for ABEC ratings exist in other countries, such as ISO (International Organization for Standardization), DIN (German Institute for Standardization), and JIS (Japanese Industrial Standards). Understanding these global equivalents allows for better comparison and selection of bearings that meet international standards. Below is a table showing the ABEC ratings alongside their ISO, DIN, and JIS equivalents:

ABEC | ISO 492 | DIN 620 | JIS B1514 |

ABEC 1 | Class Normal | P0 | Class 0 |

ABEC 3 | Class 6 | P6 | Class 6 |

ABEC 5 | Class 5 | P5 | Class 5 |

ABEC 7 | Class 4 | P4 | Class 4 |

ABEC 9 | Class 2 | P2 | Class 2 |

These global standards ensure that the bearings meet specific precision and performance criteria, regardless of where they are manufactured. When selecting skateboard bearings, it’s important to consider these standards, especially if your business operates internationally.

For more detailed information on our certified high-precision bearings, visit our certifications page.

Sealing and Lubrication of Skateboard Bearings

Proper sealing and lubrication are essential for extending the life of skateboard bearings and maintaining their performance. The type of seal and lubricant used can significantly affect the bearing’s durability and functionality.

Sealed Bearings

Sealed bearings are designed to keep out dirt, dust, and moisture, making them ideal for outdoor skateboarding. The seals help maintain the lubricant inside the bearing, reducing the need for frequent maintenance.

Perfect for outdoor use or in environments where the skateboard will be exposed to debris or moisture.

Open Bearings

Open bearings do not have seals, making them more susceptible to dirt but easier to clean and lubricate. They offer smoother performance in controlled environments, such as indoor skateparks.

Best for indoor use or for skaters who regularly clean and maintain their bearings.

Choosing the Right Lubricant (Manufacturer’s Recommendation)

Image Credits: IBT Industrial Solutions

If you are using or going to use ZHY bearing, we can walk you through everything you need to know about lubrication. Using the correct lubricant is vital for reducing friction and preventing wear. Regularly lubricating your skateboard bearings will ensure they stay in top condition, providing a smooth and fast ride. Ensure that bearings are cleaned and re-lubricated regularly, especially if used in harsh environments.

How to Choose a B2B Skateboard Bearing Manufacturer

According to a report by McKinsey, supply chain disruptions have caused companies to reevaluate their supplier networks, with 88% of companies reporting issues related to delays in deliveries and supply shortages. This highlights the importance of choosing a supplier with robust production capacity and reliable delivery times, especially for B2B clients who depend on consistent supply. To schedule a call with us, contact ZHY Bearings.

Criteria for Selecting Suppliers

Choosing the right supplier is critical to ensuring quality and reliability:

Quality Certifications and Industry Standards: Always opt for suppliers who have the necessary certifications, such as ISO, to guarantee high-quality products. Our company is certified, ensuring that all our bearings meet industry standards. Learn more on our certifications page.

Production Capacity and Delivery Times: Ensure that the supplier can handle large orders and deliver them on time. This is especially important for B2B clients who need consistency in supply.

Importance of Long-term Partnerships

Building long-term partnerships with suppliers offers multiple strategic advantages that can enhance your business’s overall productivity, cost-efficiency, reliability, and product quality. Here’s a breakdown of the key benefits:

Price Competitiveness and Service Support

Long-term partnerships often lead to better pricing through bulk purchases and negotiated discounts, reducing procurement costs. Established relationships result in faster response times and prioritized service, ensuring prompt issue resolution.

Technical Support and After-sales Service

Suppliers familiar with your specific needs offer customized technical support and reliable after-sales service, including maintenance and troubleshooting, due to their investment in maintaining a strong relationship.

Improved Product Quality

Long-term suppliers consistently meet quality standards and collaborate on product improvements and innovations, ensuring that bearings meet your specific requirements.

Increased Reliability and Trust

Trustworthy suppliers ensure a steady supply of bearings, minimizing disruptions and proactively addressing potential issues, reducing downtime and operational risks.

For those interested in exploring customized options, visit our custom bearings page.

Conclusion

Skateboard bearings play a pivotal role in the performance and safety of skateboards. Understanding the different types, materials, and precision grades, along with selecting the right supplier, is crucial for any B2B client looking to make an informed decision. By considering these factors, you can ensure that you choose the best skateboard bearings to meet your needs.